Scaffolding Mold Wales: There's a high probability that you are going to have to get some scaffolding put up, if you're planning to do some major works on your property such as putting in new windows, re-felting the roof, having a chimney stack refurbished or repointing your home's brickwork. This will make the work easier and make the site safer for both the workforce and your family. So that you can get this process done properly, you will need to locate a decent scaffolding company to examine the construction area, provide you with a quote, and schedule for your scaffolding to be set up. Scaffolding is a task for the experts and shouldn't be trusted to cowboys, therefore if a quotation sounds too good to be true - it's likely that it is!

What is Scaffolding?: A system for providing workers with a sturdy but short-term platform for accomplishing required work on houses and other structures, scaffolding is typically made from steel tubes and fittings that are clamped together and boarded out with timber planks. And it isn't only construction workers who get protection from the scaffolding, because it also protects pedestrians and those residing or working in the building, from falling dust and debris and other potential threats. Dependant upon what kind of work is going to be done, Health and Safety regulations will call for a thorough risk assessment to determine if scaffolding is necessary.

The various fittings that go together to build a scaffold include: spade ends, sills, right angle clamps, putlogs, scaffold boards, limpet clamps, guard rails, board clamps, ladders, sole boards, diagonal braces, swivel clamps, couplers, midrails, standards, ladder clamps, toeboards, base plates, facade braces and ledgers.

To confuse the situation even more, there are confined space scaffolds, tower scaffolds, double scaffolding (masons scaffolding), rolling scaffolds, tube and fitting scaffolding, trestle scaffolding, shoring scaffolds, patented scaffolding, cantilever scaffolding, suspended scaffolds and single scaffolds, each kind serving its own specific purpose. The most common type and the one which the majority of property owners in Mold will likely need for their home improvements or repairs is the single or bricklayer's scaffold. On the other hand, when it's a commercial premises or building that's having work done to it, any of the above mentioned styles may be needed.

Using a scaffolding company that is experienced and who has been approved by the local authority is always the best course of action to take whenever you need scaffolding done. A number of safety assessments will have to be done on the scaffolding, and these should be carried out prior to use, routinely every seven days, after bad weather and after adjustments or modifications. If it encroaches onto the a highway or pavement, you'll need to get authorization from the local authority. Permits like this are needed for stagings, hoarding, access towers, pedestrian barriers, scaffolding and additionally for positioning builders plant or skips. Any scaffold that's erected on a public highway must by law be equipped with safety lighting. The European Standard, BS EN 12811-1 is the legislation that any scaffolding in the British Isles needs to comply with.

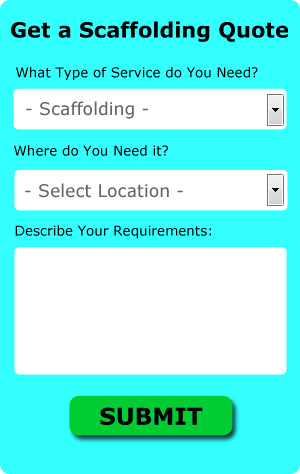

When you seek scaffolders in Mold, you might become aware of a couple of well known scaffolding contractors operating in the region. Their conspicuous advertising billboards on scaffolds throughout the area can be hard to miss. Your selection process can begin with your familiarity with these local companies. Consider using Bark.com, a platform that streamlines the process by connecting you with local scaffolders and tradespeople, to expand your options. By using this strategy, you can save a significant amount of time and energy. In no time, you'll have a sufficient pool of potential scaffolders to make a well-informed decision for your construction project, ensuring an efficient and safe scaffolding solution tailored to your needs.

Physically challenging, the role of a scaffolder also demands a considerable degree of technical skill. A thorough understanding of the intricacies of different scaffold designs, like suspended, birdcage, and independent scaffolds, is necessary for scaffolders, as each has its own unique requirements. Scaffolders must work out weight loads and employ suitable bracing and ties to guarantee the scaffold's stability. Mastery of these technical details is critical, because collapses or accidents can occur from improperly installed scaffolding, putting workers at great risk.

Scaffold Tower Hire Mold - If the project is a limited one, and you only need to hire a scaffold tower in Mold, your possible options will be a bit wider. There are various locations from where you will be able to hire a tower scaffold and these include builders merchants, tool hire companies, and sometimes even from a scaffolding company. HSS, Jewson, Hire Station, Travis and Perkins or other nearby tool hire businesses are likely locations to try.

Because they have to be easy to wheel around in situ and also easily transported, lightweight aluminium tubing is typically used in the construction of tower scaffolds. They're commonly available in different sizes and styles. Some of the more prevalent forms are microfold towers, span access platforms, double width scaffold towers, stairwell access towers, single width alloy towers, folding indoor scaffold towers, guard rail scaffold towers, single man towers, folding low level platforms, tower bridge decks, non-conductive towers, podium steps, cantilever scaffold towers and similar custom scaffolding towers. It might even end up being cheaper for you to purchase a basic scaffold tower, if you've got loads of work to complete on your home.

Understanding the various components and kinds of scaffolding that are available is crucial if you're undertaking a construction project that requires it. Clamping and tightening together a complex system of fittings and tubes, as discussed in the article on scaffolding, creates a secure working platform at height.

It's worth mentioning that scaffolding systems can include extra features such as loading bays, stairs and hoists, making it easier to transfer equipment and materials to and from the scaffold platform in addition to the components mentioned in the article.

Ensuring approval by the local council and adherence to necessary safety regulations is crucial when choosing a scaffolding company in Mold. Safety can be ensured by obtaining any necessary permits for scaffolding that encroaches on a pavement or public highway, as well as performing routine safety checks before and during the use of the scaffold.

Safety is paramount for homeowners and business owners alike with regards to scaffolds. The safety and efficiency of your construction project can be ensured by choosing an experienced and reputable scaffolder in Mold.

The Skill of the Scaffolder: Construction with Safety in Mind

The assembly of a scaffold is a demanding task that calls for a particular skillset. Presented below are the key qualities essential to a competent scaffolder:

Physical Abilities:

- Head for Heights: Part of the scaffolder's job is operating at elevated levels. They need to have a head for heights and possess an acute awareness of space.

- Agility and Balance: The construction of scaffolding regularly requires manoeuvring through confined areas and traversing a complex maze of metal, occasionally at considerable elevations. Scaffolders must possess excellent balance and agility to navigate these spaces with safety and certainty.

- Strength and Stamina: The components of a scaffold can be heavy. Scaffolders require a good level of stamina and strength to lift, position and secure these components throughout the erection process.

Communication Skills:

- Clear Communication: The collaboration between scaffolders, supervisors, engineers and construction workers is underpinned by the necessity for clear communication, ensuring collective knowledge of the scaffolding blueprint, possible dangers, and the restrictions regarding weight.

- Effective Problem-Solving: Scaffolding projects can encounter unforeseen obstacles. Scaffolders need good problem-solving skills to identify solutions and adapt their approach while maintaining safety standards.

Safety Focus:

- Safety Awareness: Scaffolders act as safety guardians on the building site. They constantly monitor the condition of the scaffold, ensuring it adheres to safety regulations. They also have the responsibility to report any unsafe work practices or potential hazards to others.

- Inspection Procedures: Conducting frequent inspections is vital for upholding a secure working environment. Scaffolders possess the training necessary to spot potential risks, such as loose components, faulty joints or damaged parts, and they swiftly rectify these problems to avoid mishaps.

- Fall Protection Protocols: The training for scaffolders comprehensively covers fall protection measures, including the appropriate utilisation of personal protective equipment such as safety nets, harnesses and lanyards, ensuring that fall protection gear is used correctly by everybody on the scaffold.

Technical Expertise:

- Reading Blueprints: Scaffolders diligently translate blueprints into reality. By figuring out the specifications and layout, they determine the anchor points, weight restrictions and dimensions required for an effective and safe scaffold.

- Structural Integrity: With a profound knowledge of load-bearing capabilities, they can assess the distribution of weight throughout the scaffolding and pinpoint potential vulnerabilities, guaranteeing the structure's ability to safely bear the combined weight of materials, equipment and workers.

- Component Knowledge: With a familiarity with the different elements of a scaffold system, including base plates, platforms, tubes, braces and couplers, scaffolders know how each component functions and collaborates to establish a stable construction.

By excelling in these essential skills, scaffolders are key to maintaining the safety and efficiency of building projects. Serving as the construction industry's foundation, they permit others to confidently rise to new heights.

Now, you might have navigated to this page searching for "scaffolding Mold", not due to the fact that you reside in Mold itself, but perhaps in one of the surrounding areas like for example Bryn-y-Baal, Llanferres, Cadole, Leeswood, Gwernymynydd, Prenbrigog, Treuddyn, New Brighton, Nercwys, Mynydd Isa, Sychdyn, Pantymeyn, Maeshafn, Cilcain, in these postcodes: CH7 1HS, CH7 1AP, CH7 1EH, CH7 1LW, CH7 1JW, CH7 1GF, CH7 1HH, CH7 1HF, CH7 1BP, and CH7 1QF, or somewhere similar. But, there's no need to be concerned because Mold scaffolding services frequently operate in these locations as well and will usually be happy to provide you with these services.

Scaffolding Signage

Without the necessary scaffolding signage, the safety of workers and the public in construction or maintenance projects involving scaffolding can be jeopardised. Signage serves to notify the workforce and the public of the presence of scaffolding and potential risks. Scaffolding signage may comprise of information signs, warning signs and directional signs, which could include contact details for the scaffolding contractor or emergency services.

Without the necessary scaffolding signage, the safety of workers and the public in construction or maintenance projects involving scaffolding can be jeopardised. Signage serves to notify the workforce and the public of the presence of scaffolding and potential risks. Scaffolding signage may comprise of information signs, warning signs and directional signs, which could include contact details for the scaffolding contractor or emergency services.

The signs must be easily visible and legible from a distance, while also adhering to applicable health and safety legislation. Scaffolding signage helps to reduce the risk of accidents and injuries by drawing attention to potential dangers and providing important information to workers and the public. Scaffolding companies in Mold must ensure that suitable signage is in place before erecting any scaffold structure. By maintaining and correctly positioning scaffolding signage, a company can exhibit its commitment to safety and compliance with legislation while also increasing safety. In large and complex projects, scaffolding signage can serve as a wayfinding tool, aiding the workforce and visitors in navigating the site, while also providing safety information.

Top Scaffold Safety Guidelines

By following a few straightforward safety tips, you should be able to prevent falls from scaffolding in Mold. The chances of an accident are always there, regardless of whether it is a stationary scaffold or a mobile scaffold. Regardless of the kind of scaffold that's being used, adherence to safety guidelines is a must, because serious injury generally results when falling from high places.

First of all, having a capable authority to take care of the scaffold on-site is the most important step to take. This supervisor should be the person who should oversee all of the scaffolding construction. Other services like assistance in scaffold erection, will be offered by any honest scaffolding company in Mold. Even so, to deal with any scaffold related issue that arises, a trained overseer who must always be available. It's a given that it is really important to follow the manufacturer's instructions whenever scaffoldings are being assembled in Mold. For advice and clarity, you should phone the manufacturers if you have any concerns. There's nothing wrong in seeking help when needed.

Whether it's a mobile or stationary scaffold, it's important to make certain that no one works on the scaffolds when the weather is windy. In Mold, most of the accidents involving falling from heights usually occur during windy weather. Making sure that scaffolds are a "no-go" zone in such weather conditions, is the job of the safety supervisor. It's important to check if a scaffold is leaning to one side or unbalanced before any person is permitted to step on to it. Checking this should be mandatory for everybody before working on any of the scaffolding. This will appreciably reduce the amount of accidents that occur on-site.

Loose bricks or concrete blocks should never be used for supporting a scaffold. Remember, if the supplier says that there is foundation necessary for scaffolding, particularly if it were to be set up on a solid surface, then it's in your best interests to follow this advice.

Wedging or chocking the wheels is crucial when a mobile scaffold is being used. This will prevent the mobile scaffolding from rolling. With aluminium scaffolds, the chance of rolling is pretty high, due to the fact that it is incredibly light. Checking that the scaffold wheels are locked is therefore really important.

Finally, it is a definite no-no to attempt to move a mobile scaffold while somebody is working on it. Many of the fall accidents involving scaffolding occur due to this error.

Scaffold Hoardings and Fences

Scaffolding hoardings and fences are non-permanent structures that are frequently used in events, building sites, or any area that requires non-permanent boundary or screening. These structures are normally made out of metal, timber or plastic and can be erected easily and quickly to provide a secure barrier around the work site or event.

Scaffolding fences are frequently used to surround scaffolding systems, making sure that the workmen and public are protected from the hazards of unstable structures or falling debris. The fences can be adjusted to fit the size and configuration of the scaffold, making them a practical and versatile solution for most work sites.

Hoardings, on the other hand, serve the purpose of concealing public works, construction sites or event preparation. They're built from materials like corrugated metal, plastic panels or wood sheets and can graphic designs painted on them to create an attractive and eye-catching screen. Hoardings are used to maintain the privacy and appearance of the area.

When it comes to ensuring the safety and security of workmen, the public, and the environment during events or construction projects, scaffolding fences and hoardings play a crucial role. They are durable, simple to install, and can be removed swiftly once the job is done.

Scaffolding Weather Protection

Ensuring the continued efficient and safe operation of workers in all sorts of weather conditions necessitates the implementation of comprehensive scaffolding weather protection measures. Protecting scaffolding from rain, wind, snow, and other harsh elements is achieved by constructing temporary structures around it.

Weather protection systems for scaffolding often employ the following methods:

- Temporary roofs: Comprising metal frames and waterproof polycarbonate panels or tarps, these temporary structures offer overhead protection from debris, snow and rain, allowing work to continue seamlessly regardless of weather conditions.

- Scaffold Encapsulation systems: Entirely enclosing scaffolding with weatherproof materials, these systems create controlled workspaces for sensitive tasks or to effectively contain dust and debris.

- Scaffold shrink-wrap: This durable plastic sheeting is tightly wrapped around the scaffolding using a heat gun, forming an impermeable barrier against water and other elements.

By implementing effective weather protection, building projects can reap a variety of benefits.

- Protects local ecosystems: By safeguarding nearby areas from dust, debris, and runoff, weather protection minimises the environmental impact of construction activities.

- Confining debris and dust release: Encapsulated scaffolding systems are effective at containing dust and debris, preventing their uncontrolled spread into the encircling environment.

- Preserving material quality: Shielding building materials from the elements, prevents damage from wind, rain and snow, ensuring their longevity and reducing project expenses.

- Protecting workers from the harsh elements: Facilitates uninterrupted work amidst inclement weather, preventing project setbacks and maintaining worker well-being.

Investing in suitable scaffolding weather protection systems is essential for safeguarding worker health and safety, enhancing project productivity, and minimising environmental degradation during construction projects.

Temporary Roofing Scaffolds Mold

For secure and safe rooftop access in construction or repairs, temporary roof scaffolds are indispensable. Creating a stable platform with metal poles and planks, these structures enable workers to perform their tasks safely and without the risk of falling. When working on steep or high roofs in Mold, these are especially beneficial, as ladders are neither practical nor safe.

As well as enhancing safety, temporary roof scaffolds shield both workers and the property from the weather during any construction work. Covered in reinforced, laminated PVC sheeting these scaffolds offer weather protection and waterproofing, so that work can continue on your project regardless of any unfavourable weather conditions.

The installation of temporary roof scaffolding requires setting up a framework around the building, ensuring it's strong enough to support materials and workers. To suit the requirements of the job, the scaffolding can be adapted to different angles and heights, offering necessary flexibility. Guardrails and toe boards are safety features that are often added to further prevent the risk of accidents.

Temporary roofing scaffolds aren't just for large building projects; they're also great for smaller repairs and maintenance tasks. Home and business owners in Mold find them a cost-effective solution as they can be hired for short-term use. By providing a secure and dry workspace, these temporary scaffolds help make sure that roofing work is carried out safely and efficiently. (Temporary Roofing Scaffolds Mold)

Scaffold Dismantling

The process of taking down scaffolding is just as vital as the initial setup, requiring a good deal of care, precision, and expertise. Once a project is wrapped up, it's important to remove the scaffolding safely to ensure that the site can be cleared without risking anyone's safety. While it may seem like a simple task, dismantling scaffolding actually involves careful planning to prevent any accidents, as even a small error can result in serious issues. So, it's really a good idea to leave it to the professionals who are trained to do this work.

A professional team will carry out the dismantling process methodically, making sure that each section of the structure is taken down in the correct order. They'll work from the top down, removing sections one at a time to keep everything balanced and stable during the process. This careful approach not only minimises risks but also ensures that the area around remains safe for workers, property, and the public. With their expertise and proper tools, these professionals can also identify and address any unexpected problems that might crop up during dismantling, which ultimately saves time and reduces stress.

Choosing to hire specialists for scaffold dismantling goes beyond just ensuring safety; it's also about getting the job done efficiently. They work quickly and to a high standard, allowing your site to return to normal in no time. It doesn't matter if it's for a home makeover or a major commercial project in Mold - having the right team makes a tremendous difference. When the dismantling is managed well, everything proceeds smoothly, giving you one less concern to deal with. (Tags: Scaffold Dismantling Mold).

Scaffold Boards Mold

We've all seen scaffold boards on building projects in Mold, and many Mold householders have got scaffold boards around their gardens and homes. Often used for bridging muddy patches, between ladders for decorating, for raised beds in the garden, and a great many other possible uses, scaffold boards are usually regarded as strong and durable. That said, many of these uses can be hazardous, and we're certainly not advocating any of those uses here!

The correct and intended use of scaffold boards in Mold is essentially to create a sturdy and safe platform for those working at height on scaffolding. Installed horizontally along scaffold lifts, these boards must be given support at evenly spaced intervals which are based upon various variables, but in particular by the grade and quality of the scaffold boards that are being used.

Scaffold boards in the British Isles are traditionally 225mm wide, 38mm thick, and come in lengths ranging from 5 feet (1.5m) to 13 feet (3.9m). To stop the exposed and weaker end grain of the boards from splitting, timber scaffold boards are easy to identify by the galvanised metal band that's nailed to the ends of each board. Scaffold boards are available in a variety of grades and types, and can be made out of materials other than timber.

The Different Types of Scaffold Boards

Grade "A" Scaffold Boards - For several decades scaffolders throughout Great Britain have frequently used grade "A" scaffold boards and largely looked on them as the standard board. However, though the name suggests otherwise, they're not the best quality scaffold boards, and actually aren't up to British Standards requirements. They shouldn't be the preferred choice on a building project, and they have been known to break on occasion.

BSI Standard Scaffold Boards - These scaffold boards do observe British Standards requirements (BS 2482:2009) and are recommended for use on-site. They're either machine or visually graded and should be so marked on the metal end band. It is recommended that this type of board should be supported at 1.2 metres (3.9 feet) intervals in order to be fully safe.

Plastic Scaffold Boards - Mold scaffolding contractors who prefer boards which are anti-slip, last longer and are more rot and water resistant, can choose plastic scaffold boards.

Steel Scaffold Boards - Compliant with British Standards specifications (BS EN 12811-1), galvanised metal scaffold boards are fire retardant and are durable and extremely strong.

Flame Retardant Scaffold Boards - If there's a requirement for wooden scaffold boards that are flame or fire retardant to Class C of the British Standards BS EN 13501-1, these can be purchased.

Scaffold Debris Netting

Scaffold debris netting is a protective mesh material installed on scaffolds to contain and prevent debris from falling. It acts as a safety measure to safeguard workers, passers-by, and surrounding areas from possible hazards. The netting is skillfully designed to combine durability, lightness, and simple installation. It functions as an effective barrier, effectively substantially minimising the risk of falling objects and lessening the potential for damage or accidents. Scaffold debris netting plays a pivotal role in establishing the safest possible working environment on building sites in Mold. Scaffold netting also contributes to the preservation of an orderly and neat work environment by effectively gathering and containing debris, improving the cleanliness of the construction site. The careful design of scaffold debris netting is a response to the specific demands of building sites. This product is engineered to be hard-wearing enough to withstand prolonged exposure, the rigours of construction activities and adverse weather conditions. Ensuring both installation ease and manoeuvreability, the netting remains lightweight, despite its durability. Its simplicity in application adds to the efficiency of construction projects, as it can be quickly installed and removed when necessary. (24862 - Scaffold Debris Netting Mold)

Scaffold debris netting is a protective mesh material installed on scaffolds to contain and prevent debris from falling. It acts as a safety measure to safeguard workers, passers-by, and surrounding areas from possible hazards. The netting is skillfully designed to combine durability, lightness, and simple installation. It functions as an effective barrier, effectively substantially minimising the risk of falling objects and lessening the potential for damage or accidents. Scaffold debris netting plays a pivotal role in establishing the safest possible working environment on building sites in Mold. Scaffold netting also contributes to the preservation of an orderly and neat work environment by effectively gathering and containing debris, improving the cleanliness of the construction site. The careful design of scaffold debris netting is a response to the specific demands of building sites. This product is engineered to be hard-wearing enough to withstand prolonged exposure, the rigours of construction activities and adverse weather conditions. Ensuring both installation ease and manoeuvreability, the netting remains lightweight, despite its durability. Its simplicity in application adds to the efficiency of construction projects, as it can be quickly installed and removed when necessary. (24862 - Scaffold Debris Netting Mold)

More Mold Tradesmen: When you're looking for Mold scaffolders, you could also be interested in pebble dashing in Mold, roof cleaning in Mold, chimney repairs in Mold, gutter cleaning in Mold, aerial installation in Mold, roofers in Mold, solar panel installation in Mold, cladding installation or replacement in Mold, rubbish removal in Mold, bricklayers in Mold, loft conversion in Mold, SKIP HIRE in Mold, window installers in Mold, and other tradesmen.

Local Scaffolding Enquiries

Recently posted scaffolding job postings: Charles and Alexandra Davies wanted a quotation for light scaffolding with 2 platforms for fitting windows on their terraced home near New Brighton. Madison Owen asked for a quotation for hiring scaffolding for her semi-detached property near New Brighton. Adam Grant wanted a quotation for front and rear scaffolding up to eaves on his semi-detached house in Cadole. Hannah Edwards asked for a quotation for hiring scaffolding for her semi-detached property near Maeshafn. Jason and Alyssa Booth asked for a quote for a tin hat scaffold on their terraced property in Gwernymynydd. Alexander and Samantha Davies wanted a quote for loft conversion scaffolding on their farmhouse in Maeshafn. Emily Booth needed a price quote for two scaffolding towers on her house near Pantymeyn. Sarah Spencer in Mynydd Isa asked "are there any reliable scaffolders near me?". William Spencer wanted a quote for a covered scaffolding for fixing the roof on his terraced house near Cadole. Danielle Anderson wanted a quote for scaffolding on two sides of house to remove chimney stack on her property near Treuddyn. Alexander Clark wanted a quotation for front and rear scaffolding up to eaves on his semi-detached house in Cadole. Nathan Clark from Gwernymynydd needed an internal scaffold to enable safe working on an industrial building. Robert Ellis wanted a price quote for scaffolding to replace the roof on his detached property near Prenbrigog.

Mold Scaffolding Tasks

Mold scaffolders should be able to help with supply and erection of scaffolding, walkway scaffolding, highway maintenance services, tube & fitting scaffolding, roof scaffolding, trestle scaffolds, bridge scaffolding in Mold, scaffolding solutions in Mold, tower scaffolding, scaffold tower hire, module scaffolding, hoarding scaffolding, access scaffolding, scaffold removal, restoration scaffolding in Mold, scaffold towers in Mold, confined space scaffolds, affordable scaffolding, rolling scaffolds, bricklayer's scaffolds, scaffolding licences, the hire of scaffold boards, suspended scaffolding, scaffold guardrails, access staircases/handrails, scaffold sheeting, pedestrian barriers, patented scaffolds, custom scaffolding, scaffolding signage and similar scaffolding services. Listed are just a handful of the tasks that are conducted by people specialising in scaffolding. Mold providers will be happy to tell you about their entire range of services.

Scaffolders Near Mold

Also find: Gwernymynydd scaffolders, Mynydd Isa scaffolders, Cadole scaffolders, Maeshafn scaffolders, Cilcain scaffolders, Bryn-y-Baal scaffolders, Llanferres scaffolders, Nercwys scaffolders, Treuddyn scaffolders, Prenbrigog scaffolders, Sychdyn scaffolders, Pantymeyn scaffolders, Leeswood scaffolders, New Brighton scaffolders and more. The majority of these locations are serviced by contractors who do scaffolding. These accomplished specialists bring a wealth of knowledge and expertise to the table, making sure that scaffold structures are not only erected correctly but also safely. In their approach, maintaining strict compliance with safety regulations and standards is essential to foster a working environment that heightens productive output and minimises the risk of mishaps. By clicking here, scaffolding quotes are available to local home and business owners.

More: Scaffolds, Scaffolding Specialists, Domestic Scaffolding, Scaffold Companies, Scaffolders, Scaffolding Firms, Construction Scaffolds, Residential Scaffolding, Shoring Scaffolds, Scaffolders, Scaffolding Contractors, Domestic Scaffolding, Scaffolding Services, Scaffolding Services, Scaffolding Services, Scaffolding Specialists, Scaffold Specialists, Scaffolding Contractors, Residential Scaffolding, Scaffold Rental, Scaffolding Specialists, Scaffolding Specialists, Scaffold Rental, Scaffolding, Cheap Scaffolders, Scaffolding, Cheap Scaffolders, Scaffolds, Shoring Scaffolds, Residential Scaffolding.

Commercial Scaffolders Mold - Scaffolding Wrapping Mold - Scaffold Hire Mold - Residential Scaffolders Mold - Scaffolding Quotations Mold - Scaffolding Near Me - Scaffolders Mold - Scaffold Companies Mold - Temporary Scaffolds Mold